|

GTO Axle Identification Overall Housing Dimensions Size for the standard

mid-year 1966 and later GTO differential is as follows: Axle flange to axle flange is 60

15/16 inches Subtract 1" from above

measurements for production mid-year 1966 and earlier No wider unit should be used, but

a narrower unit can easily be used with the bonus of using a standard wheel

offset. (A suggested GTO maximum wheel

width with standard axle is approximately 8". This means the rim

is 9" wide from outside rim to outside rim. In order to fit

properly with the stock axle, a wheel with 5" backspacing will give

4" to the outside of the rim from the mounting surface. A 2 inch

narrower axle would allow a normal rim to be used with no offset.) GETTING WIDE TIRES TO FIT: Bolt pattern is 5 on 4.75" same

as Chevy Malibu - so very common wheel. What's not so common is

the required back spacing to get the wheel centered in our wheel wells if you

plan on running fatter tires in the rear. Mid 1966 to 1972 Rear

axle is about 61" axle flange to axle flange (where brake drums butt up

against), but early 66's before about January production were only 60". The current axle needs to be measured to

verify width, because it plays an important part in determining what rim

backspacing is necessary. The later rear axle requires a wheel with

between 5" and 5-1/4" of backspacing, while the earlier axles will

only need a wheel with 4-1/2" to 4-3/4" backspacing. Next thing is to get the maximum

width out of the back wheel tubs. The inside is easy since a mallet

will smash in the inner fender sheet metal above the frame rail until it is

slightly further away from the wheel than the frame rail. Even if there

is rubbing, it will be on a totally smooth surface. Only the very

bottom metal needs to be moved over, and nothing needs to be done up higher.

Outside edge is much more work. For some reason Pontiac

decided to use a 2" wide lip on the wheel well, and about half this

lip has to be removed. After the lip is trimmed back, the only thing

the tire can touch is the smooth rolled edge of the inner wheel well about

2" above the lip. Easiest way to properly trim things back is

to start by drilling new screw holes through the stainless molding a half

inch more to the outside of the current screw holes. Drilling one

hole at a time and moving each screw will keep things in line. After

all holes have been made and the screws all fit, take off the molding

and draw a line from each of the old screw holes to the next - this will be

the cutting line for removing about 3/4" of lip. If you cut past the screw holes, there is a

very good chance that you will remove the spot welds keeping the inner fender

attached to the quarter panel. We have

done about a dozen cars cutting up to the old screw holes and never had a

problem. This process usually goes

pretty fast using a cut-off wheel, but it is terribly messy and really good

eye protection is necessary. If you

have any doubts, a body shop could handle the cutting and it should only take

an hour of shop time. The stainless

molding can then be cut between the screw holes to match the fender lip. A good pair of tin snips can be used for

this trimming. A little sanding of the

edges will prevent future cuts and snags. When the above is completed, the

width of the wheel well will go from about 10-1/2” to exactly 12” on the early GTO's, and even wider on the 1968 to 1972 models. At this point a 275/60R15 tire can be installed

using rims with the proper backspacing.

This tire mounted on an 8” rim will be approximately 11” wide, leaving

about a half inch on each side of the tire on an 8” rim. A wider rim will also make the tire

wider. Figure something like .6”

increase in width for each inch of rim width increase.

Our GTO’s came new from the factory

with a droopy rear end, and things haven’t improved over the years. A one inch spacer installed under the rear

springs will bring the car up to level ride height. A 1-1/2” spacer will provide a very mild “California

Rake” to the front. Neither spacer

will affect ride quality since it is under the spring and won’t change the

spring rate.

10 Bolt Axle Ratio Identification:

Three different differential carriers

are used. 1) 2.56 and 2.78 ratios There was also a stronger 4 pinion

spider gear carrier installed on 4-speed cars. Codes are as follows: Note "W" on the code is

for standard differential, while "Y" on the code is for locking

differential or "Posi" rear ends.

The following codes appear on the left hand axle tube approximately 2”

to the left of the brake tube holder, or about 6” to the left of the

differential case. They are about mid

height. GTO: WB or YB 2.56

(41:16)

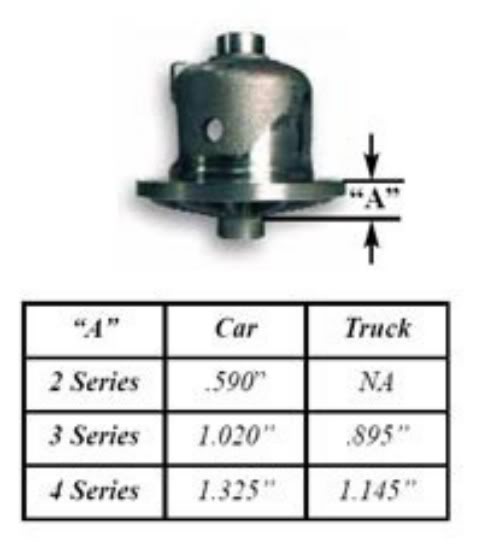

Some 12 Bolt Carrier Identification data: 12 bolt ED32088 ..............2 series......... 2.73:1 & down

Muncie transmissions: FM on Pontiac or FO on Tempest identifies

the wide ratio transmission. There are

two bands on the input shaft of a wide ratio trans. 2.52 Low FN on Pontiac or FT on Tempest

identifies a close ratio transmission.

There is only one milled band on the input shaft of a standard close

ratio trans, and no bands on a Rock Crusher. 2.20 low |

|

|

|

|